Lasercut Production Dies

|

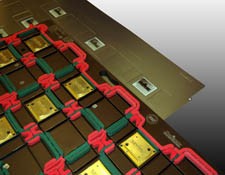

Synergy TSI utilizes the latest in CAD and Laser technologies to engineer and produce press-ready, high-efficiency steel rule production dies.

Polymer Laser Bases are required when greater strength and durability are important such as when using a milled 1 mm steel counterplate. Options include Polycore and Rayform materials. Synergy TSI utilizes the ELCEDE CimLine Rule Processing System to fabricate bent rules with unmatched accuracy and repeatability. Reverse Half Cutting, reverse creasing and simultaneous Embossing while Diecutting are just some of the special capabilities possible with tooling from Synergy TSI. Prenicking and profile Water-Jet Cut Ejection Rubbering insure a truly press-ready finished production die. Production dies from Synergy TSI can be designed to cut and crease small flute corrugated cuts from the print side enabling corrugated boxes to fold for gluing and filling with the same accuracy and repeatability as folding cartons. Production dies designed and fabricated by Synergy TSI result in greater diecutting productivity– not just in cutting and creasing but also in stripping and blanking. |

Lasercut base material choices include a range of economical woods or maple. Polymer Laminated birch provides a moisture proof surface that is oil and dirt resistant.

Lasercut base material choices include a range of economical woods or maple. Polymer Laminated birch provides a moisture proof surface that is oil and dirt resistant.